Printed Circuit Boards (PCBs) are at the heart of almost every modern electronic device, from smartphones and computers to medical equipment and satellites. They provide the physical structure for mounting and connecting electronic components while ensuring the electrical pathways remain precise and reliable. Over the years, advancements in PCB manufacturing have revolutionized the electronics industry, enabling devices to become smaller, faster, and more powerful. This article explores how PCB manufacturing shapes modern electronics, highlighting its history, process, applications, and future potential.

The Evolution of PCB Manufacturing

Early Developments

In the early 20th century, electronic circuits were wired manually using point-to-point connections. While functional, this method was bulky, unreliable, and prone to short circuits. The invention of the printed circuit board in the 1930s marked a turning point. By etching copper traces onto an insulating substrate, engineers created a more compact and durable solution.

Growth During the Digital Age

The rise of personal computers and consumer electronics in the 1980s and 1990s fueled the need for advanced PCB manufacturing. Techniques such as multi-layer boards and surface-mount technology became mainstream, allowing for denser component placement and higher-speed performance.

Modern Innovations

Today, PCB manufacturing incorporates advanced processes like high-density interconnect (HDI), flexible PCBs, and rigid-flex designs. These innovations support the demands of next-generation electronics, including wearable devices, 5G networks, and electric vehicles.

The PCB Manufacturing Process

Design and Layout

The process begins with electronic design automation (EDA) software. Engineers design the circuit schematic and translate it into a PCB layout. This step ensures that traces, vias, and component placements are optimized for performance and manufacturability.

Material Selection

The choice of substrate material is critical. FR-4, a glass-reinforced epoxy laminate, is the most common, but advanced applications may require materials like polyimide, ceramics, or high-frequency laminates. The material determines the board’s durability, heat resistance, and signal integrity.

Printing and Etching

Once the design is finalized, the copper-clad substrate undergoes a process where unwanted copper is etched away, leaving only the desired traces. This step defines the electrical pathways that connect components.

Drilling and Plating

Precise drilling creates holes for component leads and vias. These holes are plated with conductive material, usually copper, to ensure connectivity between layers in multi-layer PCBs.

Solder Mask and Silkscreen

A protective solder mask is applied to prevent oxidation and unintentional solder bridges. The silkscreen layer adds component labels, identifiers, and logos for assembly and troubleshooting.

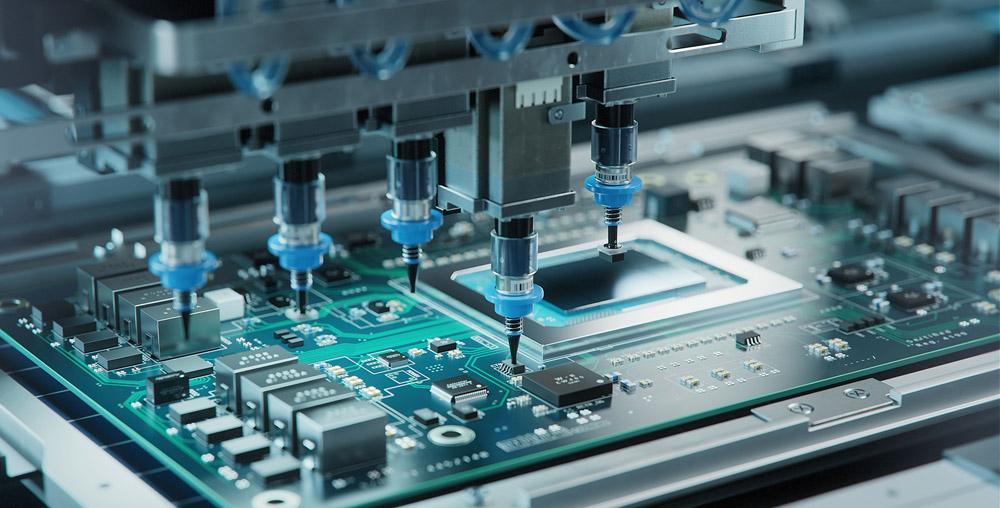

Assembly

Finally, electronic components are mounted on the PCB using through-hole or surface-mount technology (SMT). Automated pick-and-place machines ensure speed and accuracy in this step.

Impact of PCB Manufacturing on Electronics

Miniaturization of Devices

Modern PCB manufacturing allows for multi-layered boards with ultra-fine traces. This capability enables the production of smaller devices without compromising performance. Smartphones, smartwatches, and medical implants all rely on this miniaturization.

Enhanced Performance and Reliability

Advanced PCBs ensure high-speed signal transmission, reduced electromagnetic interference, and improved thermal management. This reliability is crucial for applications like aerospace, automotive electronics, and medical equipment where failures can have severe consequences.

Cost Efficiency in Mass Production

Once designed, PCBs can be manufactured in bulk with remarkable precision. Automated processes reduce errors and costs, making advanced electronics accessible to consumers worldwide.

Applications of PCBs in Modern Electronics

Consumer Electronics

Smartphones, tablets, and laptops rely on compact, multi-layer PCBs to handle processors, memory chips, and connectivity modules. Without modern PCB manufacturing, these devices would not achieve their sleek designs and high performance.

Automotive Industry

Vehicles now feature advanced driver assistance systems (ADAS), infotainment, and electric drivetrain controls. These systems depend on robust PCBs that can withstand heat, vibration, and harsh environmental conditions.

Medical Technology

From pacemakers to diagnostic imaging machines, medical devices rely on PCBs for precision and reliability. Flexible PCBs, in particular, are essential for wearable health monitors.

Telecommunications

5G infrastructure, routers, and data centers use high-frequency PCBs to manage rapid signal transmission with minimal loss. This supports the growing demand for faster internet and greater connectivity.

Aerospace and Defense

In aerospace applications, PCBs must endure extreme temperatures, radiation, and mechanical stress. Rigid-flex PCBs are commonly used in satellites, avionics, and military-grade equipment.

Emerging Trends in PCB Manufacturing

Flexible and Rigid-Flex PCBs

Flexible PCBs allow electronic devices to bend, fold, and fit into compact designs. Rigid-flex PCBs combine the durability of rigid boards with the adaptability of flexible circuits, opening new possibilities in wearable and implantable devices.

High-Density Interconnect (HDI)

HDI technology supports finer traces, smaller vias, and increased layer density. This advancement is vital for high-performance computing, smartphones, and miniaturized electronics.

Eco-Friendly Manufacturing

Sustainability has become a priority. Manufacturers are adopting lead-free solder, recyclable materials, and energy-efficient processes to reduce environmental impact.

Integration with Emerging Technologies

PCB manufacturing continues to evolve alongside artificial intelligence (AI), Internet of Things (IoT), and quantum computing. Advanced substrates and 3D printing techniques are paving the way for next-generation electronics.

Challenges in PCB Manufacturing

Complexity of Designs

As devices become more advanced, PCB layouts grow increasingly complex. Manufacturers must balance performance, manufacturability, and cost.

Heat Management

With higher component density, heat dissipation becomes a major concern. Innovations in thermal vias, heat sinks, and advanced materials are addressing this challenge.

Supply Chain Issues

Global supply chain disruptions can affect the availability of raw materials and components. This challenge emphasizes the need for local and diversified manufacturing.

The Future of PCB Manufacturing

The future of PCB manufacturing will likely focus on further miniaturization, increased integration, and sustainability. Innovations such as 3D-printed PCBs, embedded components, and smart manufacturing processes will redefine how electronics are designed and produced. Additionally, as industries like electric vehicles, renewable energy, and space exploration grow, the demand for advanced PCBs will only accelerate.

Conclusion

PCB manufacturing has played a transformative role in shaping modern electronics. From the evolution of point-to-point wiring to today’s sophisticated multi-layer, high-density boards, PCBs have enabled the development of compact, reliable, and powerful devices. They are the foundation of consumer electronics, medical technology, automotive systems, and aerospace innovations. With ongoing advancements and emerging trends, PCB manufacturing will continue to drive progress in technology and shape the future of electronics for decades to come.

When searching for a trusted repair shop, you need experience and quality service. That’s exactly what URPhone Store offers with expert Cell phone repair shop services at UR Phone services are designed to be fast, affordable, and reliable. Our certified technicians use high-quality parts to restore your phone with care.

📍 243 E Michigan St, Orlando, FL 32806

📍 5135 International Dr Suite 0, Orlando, FL 32819

📍 4783 Raleigh St, Orlando, FL 3281